Fleet Management Evolution 2000–2025

25 years ago fleets ran on clipboards. Today, they run on AI. The journey in between might surprise you.

18 September, 2025

Fleet Management Evolution 2000–2025

Fleet management is one of those industries that most people never think about until their package is late, a delivery truck blocks the street, or fuel prices hit record highs.

But if you look back at how fleets were run 20–25 years ago, you’ll be surprised at how much has changed. The shift from pen-and-paper to AI-driven platforms didn’t just make things faster, it changed the entire business model of logistics and fleet operations. Let’s walk through the biggest changes step by step.

1. From Paper to Digital — The Tech Turnaround

2000s: Paperwork and gut feeling

In the early 2000s, fleet management was still a manual job:

- Drivers filled out logbooks and mileage sheets by hand.

- Dispatchers called drivers for updates or used radio communication.

- Fuel consumption was estimated rather than tracked precisely.

Managers relied on personal experience and drivers’ honesty. If a truck was delayed, the office often didn’t know until a customer called to complain.

2010s: GPS and telematics take over

By the mid-2010s, things started changing:

- GPS tracking became standard in most commercial vehicles.

- Telematics hardware was introduced to track speed, braking, idling, and fuel use.

- Routing apps made planning more efficient and started replacing road maps.

Still, many companies were juggling Excel spreadsheets, separate compliance software, and siloed systems. Data existed, but it wasn’t always connected.

2020s: Cloud & AI-powered systems

Today, fleet management is almost entirely digital. Platforms integrate:

- Vehicle tracking

- Fuel and maintenance data

- Driver performance reports

- Compliance logs

AI adds another layer, spotting inefficiencies and predicting maintenance needs. But guess what? Many fleets still rely on spreadsheets. In fact, surveys show that around 60% of fleet managers continue to use Excel alongside software. Old habits die hard.

2. Rising Costs & Complexity

Running a fleet today is much more expensive than it was in the 2000s.

- Fuel: Back in 2000, diesel in the U.S. was cheap – around $1.50 per gallon. . Today the story looks very different. In 2025, the national average sits at about $3.78 per gallon, with sharp differences depending on the region. Fuel in Europe is even more expensive than in the U.S. A single truck can easily cost operators €75,000–90,000 per year in diesel alone.

- Vehicles: Trucks and vans are now packed with technology. Great for safety and efficiency, but expensive to repair.

- Labor: Driver shortages mean higher wages, training costs, and turnover-related expenses.

- Regulation: Compliance with environmental standards, hours-of-service rules, and reporting has added administrative layers.

No surprise, then, that 77% of fleet managers in 2025 say rising costs are their number one challenge.

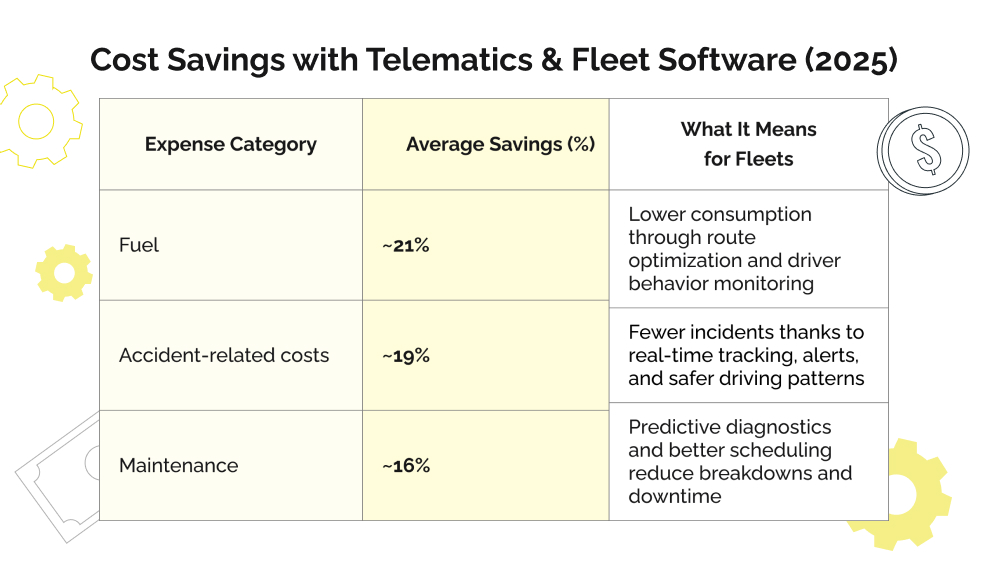

But here’s the good news: telematics and software help offset some of these expenses.

That’s not pocket change, it’s often millions of dollars saved annually.

3. AI & Predictive Maintenance: From “Fix It When It Breaks” to “Fix It Before It Fails”

Back in the day, maintenance was either:

- Reactive: wait until the truck breaks down.

- Preventive: service it at fixed mileage intervals.

Both had flaws – unexpected breakdowns were costly, and preventive maintenance often meant replacing parts too early.

Today, AI and predictive analytics are game-changers. For example:

- Penske uses telematics data from 200,000+ trucks and collects 300 million data points daily. Their AI system can tell when a part is about to fail before the driver even notices a problem.

- Predictive maintenance reduces downtime, prevents costly roadside breakdowns, and extends vehicle life.

And it’s not just the big companies. Even mid-sized fleets now adopt AI-driven tools. Instead of replacing brake pads every 30,000 miles, software tells them which specific trucks actually need it. That’s efficiency on a whole new level.

4. Electric Vehicles, Sustainability & Regulation

If you told a fleet manager in 2005 that one day they’d be considering battery-powered trucks, they’d probably laugh. But today:

- EV adoption is real but uneven. Globally, over 80% of fleets report having zero EVs. Barriers? High upfront costs, charging infrastructure, and range anxiety.

- Regional differences: In Australia, 51% of fleets have at least some EVs, while in the US and EU, adoption is slower.

- Regulations are pushing things forward: European low-emission zones, California’s zero-emission mandates, and EU “Fit for 55” policies.

But the transition is tricky. Fleets have to balance sustainability goals with real-world limitations. A delivery van in a city might go electric easily. A long-haul truck covering 1,000 km per day? That’s still a challenge in 2025.

5. Market Growth & Software Platforms

Fleet management has become a booming industry on its own.

- In 2000, it was mostly a niche service: GPS vendors, maintenance shops, and paper-based record keepers.

- By 2023, the market hit $18.6 billion globally.

- By 2028, it’s expected to more than triple, reaching $55.6 billion.

Why? Because logistics and fleet operations now rely on:

- Cloud platforms that connect all data in one place.

- Dashboards that let managers track everything from one screen.

- Predictive analytics that guide decision-making.

- Integrations with HR, compliance, and finance systems.

Fleet management went from “keeping trucks on the road” to being a strategic business function that can make or break margins.

6. More Data, More Decisions

Data is everywhere now.

- 68% of fleets use dedicated maintenance software.

- Most managers juggle multiple platforms – fuel tracking here, driver compliance there, maintenance logs elsewhere.

- 87% manage compliance digitally, but accuracy isn’t always 100%.

At the same time, there’s pushback. Around 37% of drivers dislike being monitored. Dashcams, tracking devices, and AI coaching tools can feel intrusive. Balancing efficiency with driver privacy is one of the hottest debates in 2025.

8. What’s Next? 5 Things to Watch

1. Routing that actually learns

Think GPS, but smarter. Software that doesn’t just tell you where to go – it learns from traffic jams, weather, and delivery windows to keep getting better. That’s where ML is heading.

2. Smarter fleet upgrades

AI’s helping managers figure out the perfect time to swap out old vehicles. It’s not just about fixing breakdowns anymore, it’s about balancing fuel savings, maintenance costs, and even resale value.

3. Plugging into smart cities

Fleets will be more connected to city infrastructure: traffic lights, charging points, logistics hubs etc. The road itself becomes part of the network.

4. Making life easier for drivers

It’s not all about tracking. Expect more tools built for drivers – fatigue detection, AR dashboards, even mental health support. Happier drivers = smoother operations.

5. EVs going mainstream

With cheaper batteries and more charging stations popping up, electric adoption is set to speed up, especially for last-mile and delivery fleets.

Wrapping It Up

Fleet management has come a long way. What used to be all clipboards, paper logbooks, and guesses is now AI dashboards, predictive maintenance, and real-time tracking. Fleets are smarter, greener, and more connected but also more complicated and expensive to run.

One thing is clear: technology isn’t just a bonus anymore, it’s what keeps trucks moving, deliveries on time, and costs in check. EVs, AI routing, and driver-friendly tools are just getting started, and they’re already changing the game.

At the end of the day, fleet management today is about running the whole operation smarter, faster, and ready for whatever comes next.

Let's work together to make your project a success

Contact usLast News

Thank you!

We’ve received your contact request and will contact you soon

Something went wrong

We couldn’t receive your contact request. Please try again later.